How to Test 3 Wire AC Pressure Switch: A Step-by-Step Guide

To test a 3-wire AC pressure switch, use a multimeter to measure the resistance between the terminals. If there is continuity, the switch is closed, indicating that it is functioning properly.

However, if there is no continuity, the switch may be faulty and in need of replacement.

:max_bytes(150000):strip_icc()/repair-washing-machine-water-level-fill-switch-1824607-hero-f7677789212746bdb1be2eaad58be1dc.jpg)

Credit: www.thespruce.com

Understanding The Ac Pressure Switch

Understanding the AC Pressure Switch is crucial in diagnosing AC issues. To test a 3 wire AC Pressure Switch, use a multimeter to measure voltage and continuity on the switch’s electrical contacts. Additionally, check for battery voltage on the harness side for each switch.

Closed. It opens when the pressure exceeds the preset limit.

What Is An Ac Pressure Switch?

- An AC pressure switch is a component of the air conditioning system that monitors the pressure of the refrigerant.

- It is responsible for regulating and controlling the operation of the compressor based on the pressure levels.

- When the pressure is too high or too low, the AC pressure switch will shut off or activate the compressor accordingly.

How Does An Ac Pressure Switch Work?

- The AC pressure switch is connected to the refrigerant line and detects the pressure changes.

- It consists of two terminals, one connected to the ground and the other to the compressor clutch.

- When the pressure exceeds the allowed range, the AC pressure switch opens the circuit, interrupting the power supply to the compressor clutch.

- This prevents potential damage to the compressor and other components of the AC system.

Importance Of Testing The Ac Pressure Switch

- Testing the AC pressure switch is essential to ensure the proper functioning of the air conditioning system.

- It helps identify any issues or malfunctions with the switch, allowing for timely repairs or replacements.

- By testing the AC pressure switch, you can prevent potential compressor damage, which can be costly to repair.

- Regularly testing the AC pressure switch helps maintain the overall efficiency and performance of the AC system.

- It is a crucial step in diagnosing and troubleshooting AC problems, as it helps determine whether the pressure switch is the cause of the issue.

Understanding the AC pressure switch and testing its functionality is vital for maintaining the performance of the air conditioning system. Regular testing helps identify any potential issues and allows for prompt repairs, preventing further damage to the compressor and other components.

By following the recommended testing procedures, you can ensure the proper functioning of your AC system and enjoy a comfortable driving experience.

Gathering The Required Tools And Equipment

To test a 3 wire AC pressure switch, you’ll need the right tools and equipment. Start by unplugging the switches and checking for battery voltage on the harness side. Make sure to unplug only one switch at a time to avoid any complications.

Then, use a multimeter to measure the voltage between the sensor’s connector ground and reference voltage wire. Finally, apply air pressure to the pressure port using compressed shop air to isolate any faulty circuits or sensors.

:

To properly test a 3 wire AC pressure switch, you’ll need the following tools and equipment:

- Multimeter: This instrument will help you measure electrical voltages, currents, and resistances. It is essential for diagnosing any electrical issues with the pressure switch.

- Compressed Shop Air: This is used to apply air pressure to the pressure port during testing. It allows you to simulate the conditions that the switch would encounter while your AC system is operating.

- Safety Gloves: Always prioritize safety when working with any electrical equipment. Make sure to wear safety gloves to protect your hands from any potential harm.

- Safety Goggles: Similarly, protect your eyes by wearing safety goggles. This ensures that any debris or pressure release during testing won’t cause injury.

Importance Of Using The Right Tools:

Using the right tools is crucial for accurately testing a 3 wire AC pressure switch. Here’s why it matters:

- Accurate Diagnosis: The right tools enable you to obtain precise measurements and readings. This helps you identify potential issues with the pressure switch and ensures that you accurately diagnose any problems within your AC system.

- Safety: Using the appropriate tools reduces the risk of accidents or injuries. Failing to use the right equipment could lead to incorrect readings or even electrical shocks.

- Efficient Troubleshooting: With the correct tools in hand, you can troubleshoot efficiently. This saves time and allows you to address any issues with the pressure switch promptly.

Safety Precautions To Consider:

Prioritize safety during the testing process by following these precautions:

- Turn Off Power: Before starting any testing, ensure that the power supply to your AC system is switched off. This reduces the risk of electric shock and provides a safe environment for testing.

- Follow Manufacturer Instructions: Always refer to the specific instructions provided by the manufacturer of your AC system and pressure switch. This ensures that you follow the correct procedures and guidelines for testing.

- Avoid Direct Contact: When testing, never touch any live wires or exposed electrical components. Use insulated tools and always handle wires with care.

- Inspect Cables and Connections: Before starting the testing process, inspect the cables and connections for any visible damage or loose connections. Repair or replace any faulty components before proceeding with testing.

- Work in a Well-Ventilated Area: Testing may involve the use of compressed shop air and potentially release refrigerant. Ensure that you are working in a well-ventilated area to avoid inhaling any harmful substances.

By gathering the necessary tools and adhering to safety precautions, you’re ready to test your 3 wire AC pressure switch effectively and with confidence.

Step-By-Step Guide To Testing The Ac Pressure Switch

Learn how to test a 3-wire AC pressure switch with this step-by-step guide. Find out the symptoms of a bad pressure switch, locate the switch, and perform a pressure switch bypass test to diagnose any issues.

Step 1: Locating The Ac Pressure Switch

- The AC pressure switch is a crucial component in your vehicle’s air conditioning system.

- It is typically located in the high-pressure side of the system, near the receiver-drier or condenser.

- Refer to your vehicle’s service manual or online resources to find the exact location of the pressure switch.

- Once located, ensure that the engine is turned off and the vehicle is in a safe position before proceeding to test the switch.

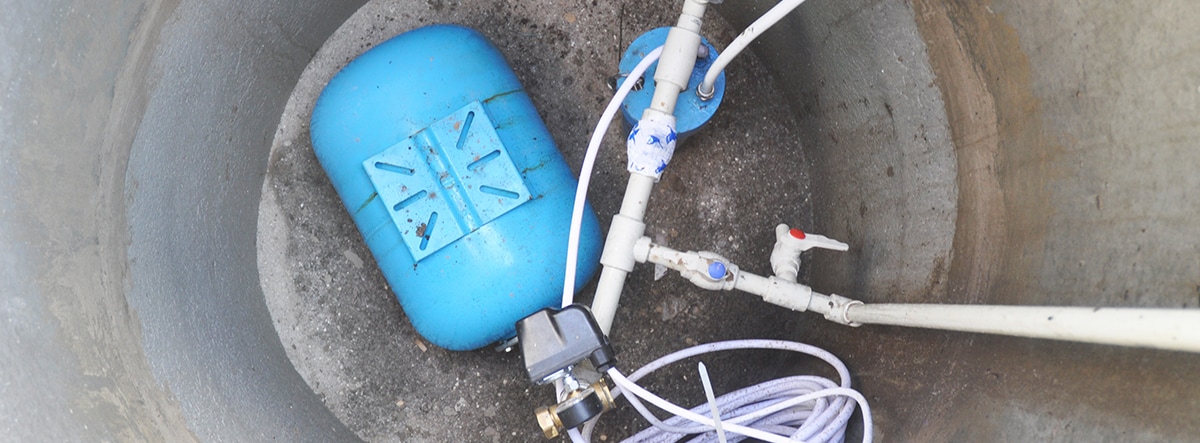

Step 2: Disconnecting The Electrical Connection To The Pressure Switch

- Before testing the AC pressure switch, it is essential to disconnect the electrical connection to ensure accurate readings.

- Locate the electrical connector attached to the pressure switch, usually a two-wire harness.

- Carefully disconnect the connector, taking note of any tabs or locks that need to be released.

- Inspect the connector for any signs of damage or corrosion, which may indicate a faulty connection.

Step 3: Testing For Continuity Using A Multimeter

- To test the continuity of the AC pressure switch, you will need a multimeter set to the continuity or resistance mode.

- Connect the multimeter probes to the terminals or pins on the pressure switch.

- If the switch is functioning correctly, you should get a reading close to zero ohms, indicating continuity.

- If the multimeter shows an open circuit or a significantly high resistance reading, it suggests a faulty pressure switch.

Step 4: Interpreting The Multimeter Readings

- When interpreting the multimeter readings, keep the following guidelines in mind:

- A reading close to zero ohms indicates continuity and a properly functioning pressure switch.

- Any open circuit or high resistance reading suggests a faulty pressure switch that needs replacement.

- It is essential to compare the readings with the specifications provided by the vehicle manufacturer for accurate assessment.

Step 5: Testing For Voltage Using A Multimeter

- Another way to test the AC pressure switch is by checking for voltage.

- Set your multimeter to the DC voltage mode and connect the probes to the terminals or pins on the pressure switch.

- Start the engine and turn on the air conditioning system to activate the pressure switch.

- The multimeter should display a voltage reading, indicating that the switch is functioning correctly.

Step 6: Interpreting The Multimeter Readings

- Here’s how to interpret the multimeter readings when testing for voltage:

- A voltage reading near the specified range indicates that the pressure switch is operating correctly.

- If there is no voltage or an unusual reading, it may suggest a faulty pressure switch or an electrical issue that requires further investigation.

Step 7: Testing The Ac Pressure Switch With Compressed Air

- In addition to electrical testing, you can also test the pressure switch using compressed air.

- Reconnect the electrical connector back to the switch, ensuring a secure connection.

- Apply compressed air to the pressure port of the switch using a pressure gauge or specialized equipment.

- Monitor the switch’s response and observe any changes in the air conditioning system’s operation.

Step 8: Isolating Any Faulty Circuits Or Sensors

- If you suspect a faulty pressure switch but want to ensure accuracy, it is crucial to isolate any other potential issues.

- Test other related components such as the compressor, refrigerant levels, or temperature sensors.

- By eliminating other potential causes, you can determine with more certainty if the pressure switch is indeed faulty and needs replacement.

Testing the AC pressure switch is a crucial step in troubleshooting air conditioning issues in your vehicle. By following this step-by-step guide, you can determine whether the switch is functioning correctly or if it needs replacement. Remember to always prioritize safety and consult a professional if you are unsure or uncomfortable with performing these tests yourself.

Troubleshooting And Common Issues

Looking to troubleshoot and test a 3 wire AC pressure switch? Check out videos on YouTube that provide step-by-step instructions on how to test and replace a faulty pressure switch using a multimeter. Don’t forget to unplug the switches and check for battery voltage before making any changes.

Common Symptoms Of A Faulty Ac Pressure Switch:

- AC not cooling: One of the most common signs of a bad AC pressure switch is when your air conditioning system fails to provide cool air even when it’s turned on.

- Cycling on and off frequently: If you notice your AC unit constantly turning on and off, it could indicate a problem with the pressure switch.

- Compressor not engaging: Another symptom of a faulty pressure switch is when the compressor doesn’t kick in, preventing the system from functioning properly.

- Inconsistent cooling: A malfunctioning pressure switch can cause inconsistent cooling, with the AC system blowing cold air one moment and warm air the next.

Potential Causes Of Ac Pressure Switch Failure:

- Electrical issues: Faulty wiring, loose connections, or corrosion can disrupt the electrical signals, leading to pressure switch failure.

- Refrigerant leak: A refrigerant leak can put additional strain on the AC pressure switch, causing it to malfunction over time.

- System overload: Extreme temperatures or excessive system workload can cause the pressure switch to fail prematurely.

- Mechanical damage: Any physical damage to the pressure switch, such as impact or corrosion, can result in its failure.

Troubleshooting Tips For Identifying The Issue:

- Check the electrical connections: Ensure that all wires are securely connected and free from any damage or corrosion.

- Test the pressure switch with a multimeter: Use a multimeter to measure the continuity of the pressure switch and compare it to the manufacturer’s specifications.

- Inspect for refrigerant leaks: Look for any signs of refrigerant leaks, such as oil stains or hissing sounds, which can indicate a problem with the pressure switch.

- Monitor system performance: Keep track of the AC system’s performance, including cooling efficiency and cycling patterns, to identify any irregularities.

Remember, troubleshooting and diagnosing AC pressure switch issues should be done by a qualified technician. These tips can help you identify potential problems, but professional assistance may be required for accurate diagnosis and repair.

Frequently Asked Questions On How To Test 3 Wire Ac Pressure Switch

How Do You Test A 3 Wire Pressure Sensor?

To test a 3 wire pressure sensor, follow these steps: 1. Measure voltage between the sensor’s ground and reference voltage wire. 2. Test the sensor by applying air pressure to the pressure port using compressed shop air. 3. Isolate the faulty circuit or sensor.

4. Check for continuity by placing test probes on the two electrical contacts. If the pressure switch is closed, there will be continuity.

How Do You Know If Your Ac Pressure Switch Is Bad?

To determine if your AC pressure switch is bad, follow these steps: 1. Locate the pressure switch in your AC system. 2. Disconnect the electrical connection to the pressure switch. 3. Use a multimeter to measure the resistance between the terminals of the pressure switch.

4. If there is no continuity or the reading is significantly different from the specified range, the pressure switch is likely faulty.

How Do You Test An Ac Sensor With A Multimeter?

To test an AC sensor with a multimeter, follow these steps: 1. Measure the resistance by touching the multimeter probes to the terminals of the AC sensor. 2. Check for continuity to determine if the sensor is closed. 3. Verify battery voltage on the harness side of the sensor.

4. Repeat these steps for each sensor, one at a time, to isolate any faulty sensors.

Is The Ac High Pressure Switch Normally Open Or Closed?

The AC high pressure switch is normally closed until the pressure reaches its upper limit, and it opens to prevent the compressor from continuing to pump refrigerant.

Conclusion

To conclude, testing a 3 wire AC pressure switch is a crucial step in diagnosing any issues with your AC system. By following the correct procedures and using a multimeter, you can accurately determine whether the pressure switch is functioning properly.

It is important to check for continuity and measure resistance to ensure the switch is closed when it should be and open when necessary. Faulty pressure switches can lead to various symptoms, such as the AC not cooling properly or the compressor clutch not engaging.

By isolating the faulty circuit or sensor, you can identify the problem and take the appropriate steps to fix it. Remember to always prioritize safety and consult with a professional if you are unsure about any aspect of AC system testing.