What Are The 4 Phases Of Planned Maintenance In HVAC: Essential Guide

The 4 phases of planned maintenance in HVAC are inspection, cleaning, testing, and repairs. Each phase ensures optimal system performance.

Maintaining an HVAC system is crucial for energy efficiency and longevity. Regular inspections help identify potential issues early, preventing costly repairs. Cleaning components like filters and coils improves air quality and system efficiency. Testing ensures that all parts function correctly, reducing the risk of unexpected breakdowns.

Repairs address any identified problems, ensuring the system runs smoothly. Consistent maintenance enhances comfort, lowers energy bills, and extends the life of the HVAC system. By following these four phases, homeowners can ensure their HVAC systems operate efficiently and reliably year-round. This proactive approach saves money and provides peace of mind.

Introduction To Planned Maintenance

Planned maintenance for HVAC systems ensures long-lasting performance. It involves regular check-ups, cleanings, and minor repairs. Planned maintenance can save money and prevent breakdowns.

Importance Of Planned Maintenance

Planned maintenance is crucial for your HVAC system. It keeps the system running smoothly. Regular maintenance reduces unexpected failures. It extends the life of your equipment.

Benefits For Hvac Systems

There are many benefits to planned maintenance:

- Energy Efficiency: Keeps your system running efficiently.

- Cost Savings: Prevents costly emergency repairs.

- Improved Air Quality: Regular cleanings ensure cleaner air.

- Consistent Comfort: Maintains a comfortable indoor environment.

| Benefit | Description |

|---|---|

| Energy Efficiency | Reduces energy use, lowering utility bills. |

| Cost Savings | Avoids expensive emergency repairs and replacements. |

| Improved Air Quality | Ensures cleaner air by reducing dust and allergens. |

| Consistent Comfort | Maintains a stable temperature and humidity level. |

Credit: www.jadeheatingandair.com

Phase 1: Inspection

The first phase in planned HVAC maintenance is inspection. Regular inspections help identify potential issues early. This proactive step ensures your HVAC system runs efficiently.

Key Inspection Tasks

- Check and replace air filters.

- Inspect the thermostat settings.

- Examine electrical connections and wiring.

- Look for refrigerant leaks.

- Assess the condition of belts and pulleys.

- Test system controls to ensure proper operation.

Tools And Techniques

Technicians use various tools and techniques during the inspection phase:

| Tool | Purpose |

|---|---|

| Multimeter | Check electrical connections and voltages. |

| Thermometer | Measure air temperature output. |

| Refrigerant Gauge | Check refrigerant levels. |

| Screwdriver Set | Tighten loose components. |

| Flashlight | Inspect hard-to-see areas. |

Using these tools ensures a thorough inspection, helping to identify and fix problems early. Regular inspections extend the life of your HVAC system.

Phase 2: Cleaning

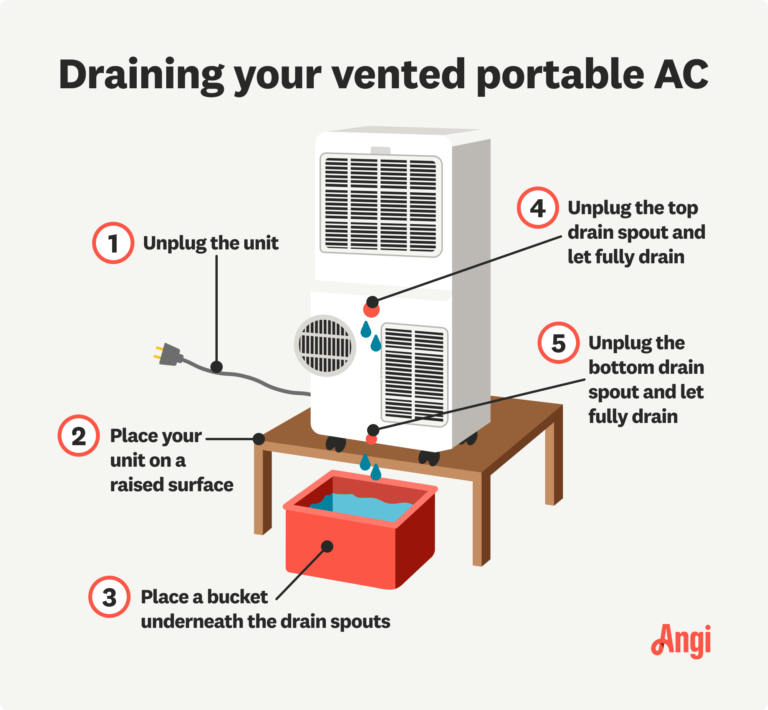

Phase 2 of planned HVAC maintenance is all about cleaning. This phase focuses on removing dirt, dust, and debris. A clean HVAC system runs smoothly and efficiently. Let’s dive into the cleaning procedures and the importance of regular cleaning.

Cleaning Procedures

Cleaning your HVAC system involves several essential steps. Here’s a breakdown:

- Filter Replacement: Change filters every 1-3 months.

- Coil Cleaning: Clean evaporator and condenser coils.

- Drain Line Cleaning: Clear the condensate drain line.

- Blower Cleaning: Remove dust from blower assembly.

- Vent Cleaning: Clean supply and return vents.

Each part must be cleaned carefully. This ensures the system works without issues.

Importance Of Regular Cleaning

Regular cleaning keeps your HVAC system in top shape. Here are some key benefits:

- Improved Air Quality: Clean systems filter air better.

- Increased Efficiency: Less dirt means better performance.

- Extended Lifespan: Clean systems last longer.

- Energy Savings: Efficient systems use less energy.

Neglecting cleaning can lead to costly repairs. It can also decrease the system’s lifespan.

Regular HVAC cleaning ensures you breathe clean air. It also saves money by reducing energy bills. Make cleaning a priority in your HVAC maintenance plan.

Phase 3: Testing

Phase 3: Testing is critical in planned maintenance for HVAC systems. This phase ensures that all components function correctly. It involves both performance and safety testing. Each type of test has its own set of checks and procedures.

Performance Testing

Performance testing focuses on the system’s efficiency. Technicians measure airflow and temperature. They also check the system’s energy consumption. The goal is to ensure optimal performance. If any part underperforms, it gets fixed or replaced.

- Airflow Measurement: Ensures air moves through ducts smoothly.

- Temperature Checks: Confirms consistent temperature levels.

- Energy Consumption: Assesses the system’s energy use.

Safety Testing

Safety testing ensures the system operates safely. Technicians look for potential hazards. They check electrical connections and gas lines. They also inspect safety controls. These tests help prevent accidents.

- Electrical Checks: Examine all wiring and connections.

- Gas Line Inspections: Ensure no leaks are present.

- Safety Controls: Test emergency shut-off mechanisms.

Phase 4: Adjustment And Calibration

Phase 4: Adjustment and Calibration is crucial in HVAC maintenance. It ensures the system operates efficiently. Proper adjustments and calibrations improve performance and extend lifespan.

Necessary Adjustments

Adjustments are essential for optimal HVAC function. These include:

- Thermostat settings: Set for accurate temperature control.

- Fan speed: Adjust for balanced airflow.

- Air dampers: Set for proper air distribution.

Technicians must check and adjust these components. It ensures the system runs smoothly.

Calibration Techniques

Calibration ensures HVAC components work precisely. Key techniques include:

- Thermostat calibration: Use a reliable thermometer for accuracy.

- Pressure sensors: Calibrate with a manometer.

- Flow meters: Use standard flow rates for proper settings.

Technicians need the right tools and knowledge. Proper calibration prevents energy waste and maintains comfort.

Credit: www.austinalpine.com

Creating A Maintenance Schedule

Creating a maintenance schedule for your HVAC system ensures peak efficiency. A well-planned schedule helps prevent breakdowns and prolongs the life of your equipment. It is essential to follow a structured plan to keep your HVAC system running smoothly.

Frequency Of Maintenance

Regular maintenance is crucial for optimal HVAC performance. Here are some recommended frequencies:

- Monthly: Check air filters and replace if dirty.

- Quarterly: Inspect and clean the coils.

- Biannually: Check refrigerant levels and inspect the thermostat.

- Annually: Schedule a professional HVAC inspection.

Seasonal Considerations

Each season brings different challenges for your HVAC system. Plan your maintenance accordingly:

| Season | Maintenance Tasks |

|---|---|

| Spring |

|

| Summer |

|

| Fall |

|

| Winter |

|

Tools And Equipment For Maintenance

Maintenance of HVAC systems requires specific tools and equipment. These tools ensure efficient performance. Having the right tools saves time and effort. Below, we explore essential tools and advanced equipment.

Essential Tools

Essential tools are necessary for routine HVAC maintenance. These tools are easy to use and commonly available.

- Screwdrivers: Various types for different screws.

- Wrenches: Adjustable and fixed wrenches for different bolts.

- Pliers: Needle-nose and channel-lock for gripping and bending.

- Multimeter: Measures voltage, current, and resistance.

- Thermometer: Checks temperature levels.

- Manifold Gauge: Measures refrigerant pressure.

Advanced Equipment

Advanced equipment enhances the efficiency of HVAC maintenance. These tools are usually more sophisticated and specialized.

| Equipment | Purpose |

|---|---|

| Leak Detector | Identifies refrigerant leaks. |

| Refrigerant Recovery Machine | Recovers and recycles refrigerants. |

| Vacuum Pump | Removes air and moisture from systems. |

| Infrared Camera | Detects temperature variations. |

| Combustion Analyzer | Checks combustion efficiency. |

Using the right tools and equipment ensures effective HVAC maintenance. It also extends the lifespan of HVAC systems. Selecting the appropriate tools is crucial for every HVAC technician.

Credit: dreamzcmms.com

Conclusion And Best Practices

Understanding the 4 phases of planned maintenance in HVAC is crucial. It helps ensure optimal performance and longevity of your HVAC system. This section provides a summary of these phases and offers best practices for maintaining your HVAC system.

Summary Of Phases

| Phase | Description |

|---|---|

| 1. Inspection | Regular checks to identify potential issues. |

| 2. Cleaning | Removing dust and debris from components. |

| 3. Testing | Ensuring all parts are working properly. |

| 4. Repairs | Fixing any identified problems. |

Tips For Optimal Maintenance

- Schedule regular inspections: Do this at least twice a year.

- Replace air filters: Change filters every 1-3 months.

- Clean components: Ensure all parts are dust-free.

- Check refrigerant levels: Maintain proper levels to avoid system strain.

- Inspect ductwork: Look for leaks or blockages.

- Test thermostat: Ensure it’s working accurately.

- Lubricate moving parts: Reduce friction and wear.

- Monitor energy bills: Unusual increases can signal issues.

Frequently Asked Questions

What Are The Four Phases Of Maintenance?

The four phases of maintenance are: 1. **Corrective Maintenance** – Fixing issues as they arise. 2. **Preventive Maintenance** – Scheduled routine checks to prevent problems. 3. **Predictive Maintenance** – Monitoring equipment to predict failures. 4. **Proactive Maintenance** – Addressing root causes to avoid future issues.

What Is Planned Maintenance Hvac?

Planned maintenance HVAC involves regularly scheduled inspections and servicing of heating, ventilation, and air conditioning systems. This ensures optimal performance and longevity.

What Are The Four Phases Of Planned Maintenance Quizlet?

The four phases of planned maintenance are: planning, scheduling, execution, and completion. These phases ensure efficient and effective maintenance.

Conclusion

Understanding the four phases of planned maintenance in HVAC can greatly enhance system efficiency and longevity. Regular inspections, preventive maintenance, corrective actions, and predictive measures ensure optimal performance. Implementing these phases reduces downtime and extends equipment life, ultimately saving costs.

Prioritize planned maintenance to keep your HVAC systems running smoothly.